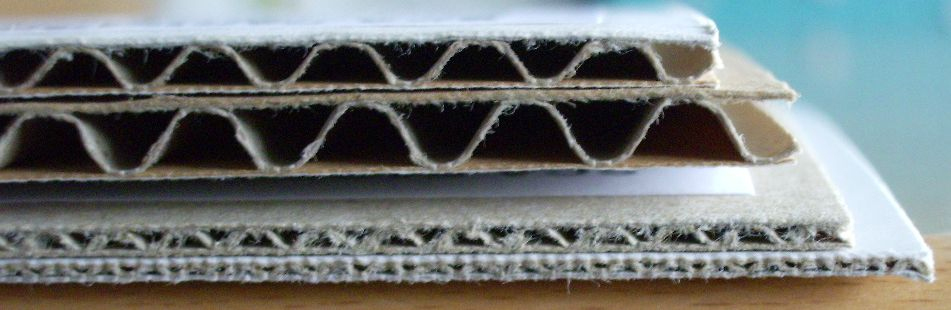

Corrugated cardboards differentiate themselves by the type of liner (the surface sheet) and the flute type (the wavy part). Flute types are defined by their thickness and the number of flutes per lineal foot. Micro-flute board belong to this type.

The thinner the flute is the lighter the packaging is since the flute requires less paper (this is called the take-up). The thicker the flute is the more protection (thicker crash zone) and insulation is provided to the product.

The number of flutes per lineal foot will directly impact the resistance to crash, the structural rigidity of the box, the accuracy of the folding operations and the printability.

| Flute type | Flute thickness (mm) | Flutes per lineal foot | Take-up |

| E | 1.6 | 90 | 1.24 |

| F | 0.8 | 125 | 1.22 |

| N | 0.5 | 170 | 1.21 |

Although there is not a significant amount of difference between the three flutes, F-Flute is half as thick as the E-flute and the N-flute being even thinner. N-flute provides almost twice as many flutes per lineal foot than the E flute.

Therefore, F and N-type micro-flute are getting an increasing interest in the Packaging industry, which is very concerned about its carbon footprint (less fiber consumption, lighter packaging, smaller volume of the packaged good for warehousing and transportation) and still wants adequate protection for the product. This is especially true for goods requiring both particular care and elegant packaging (fine foods).

In the food and beverage, cosmetics and pharma industries, F and N-type micro-flute are becoming a material of choice because of their enhanced printability and folding capabilities and still offering a more rigid packaging than E-flute. Since F and N type cardboards have a much larger number of flutes per foot, they allow more accurate folding operations.

Printing on micro-flute

Printing on corrugated board has been historically the weak point in the production process. Commonly it has been a 2 steps process: printing on paper / film and laminating onto the corrugated board. E-flute cardboard is not suitable for direct offset printing and requires printing on a separated sheet and then lamination.

Netpak Packaging has developed NetCorr, an innovative packaging solution allowing direct printing on micro-flute hence eliminating the laminating step. Netpak has focused on the F and N-flutes types of board to offer its clients a sustainable packaging solution with high quality printing and folding outcomes and a lean production process (more).

Netpak used a wide range of liners (surface sheet) to best suit the needs of the clients, from virgin fibers to 100% recycled, water resistant or grease proof, mate or glossy finish.

Do not hesitate to contact us (netpak@netpak.com) in order to discuss potential collaboration opportunities, and solutions that we can bring to you.