Opting for a packaging with window allows packaging designers and product managers for numerous creative options to enhance the product visibility and trigger customer’s curiosity. But choosing the right film is essential to achieve the best possible outcome.

3 key factors to consider

Size of the window

The window size is an important factor to take into consideration. The larger the window, the stiffer the film should be, since it will require a film with some structural strength. If the window is small, a thin flexible film could be sufficient. It is also important to consider the potential gluing surface available. While designing the packaging, allowing enough room for window gluing will reduce risks and increase production speed (and hence cost).

Stiffness and strength

High end products (pharma and cosmetic markets) will require film with a high stiffness, crystal clarity and a high gloss level, packaging with large windows will focus more on tensile strength and burst strength.

The window patch is applied on a window-patching machine which appliers adhesive to the reverse side of the carton blank in line with the perimeter of the window. The film is cut automatically from a reel and applied over the adhesive. Therefore structural strength of the film will directly impact production speed, and hence manufacturing cost.

Heat, moist and freeze

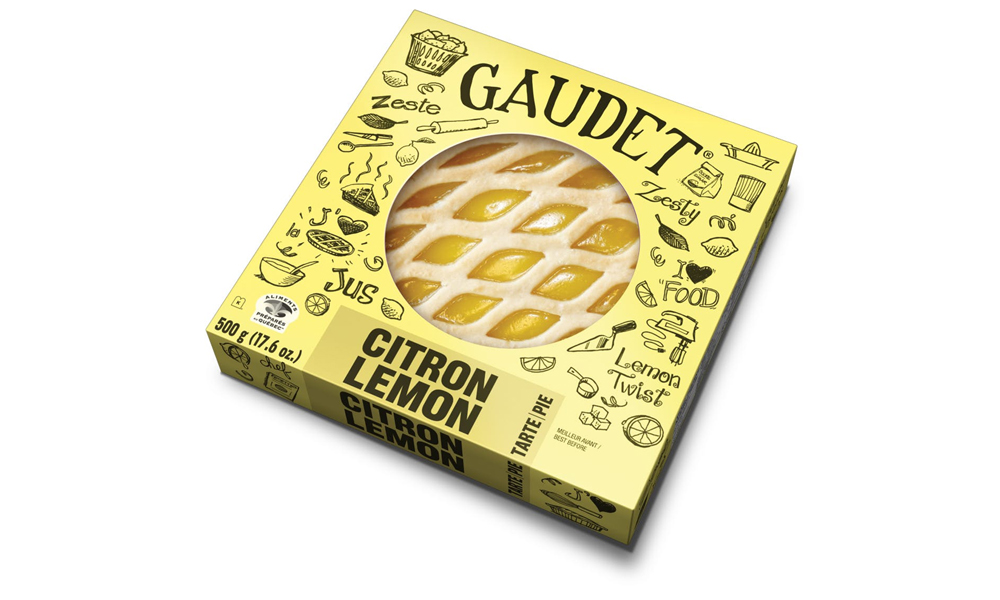

For some food products, film stability over a wide range of temperature and humidity levels will be the key factor to be considered. For example, in the bakery industry, pies will be packed while still warm (hot and steamy environment) and will be then chilled or frozen. A low quality film could be a disaster with fogging, tear or wrinkles.

The 3 main plastic films : Acetate, PET and Polypropylene

Acetate

Acetate is a cellulose-based film, a natural and renewable material that is sourced only from managed forestry. Being a cellulose based film, acetate film reacts similarly to board and tends to dry over time and stretches for a perfect rendering. Acetate film offers exceptional crystal clarity and a reflexion-free surface, and can accept ink when “write-on” property is needed. It is also known for its wrinkle resistance, greaseproofness, water resistance, dimensional stability, high gas permeability, good electrical insulation properties, and resistance to fogging and medium water vapor transmission. On the other hand tear resistance could be considered as a weakness although this is also considered as a feature for easy-tear packaging. Thanks to its excellent moisture permeability it is used widely in food packaging, especially bakery products. Its “breathability” minimizes the risk of fogging in chilled retail display cabinets. Crystal clarity and perfect finish are particularly appealing to the cosmetics industry.

Thanks to its excellent machinability and cutting properties, acetate film is perfectly suitable for high speed machinery and hence for large volumes.

PET

PET (Polyester) film is a biaxially oriented, thermoplastic film made from ethylene glycol and dimethyl terephthalate. Technical specifications of PET films are excellent gas and moisture barrier, high tensile strength, thermal, mechanical, optical and electrical properties.

Its main characteristic is its strength compared to cellulose acetate, which makes it particularly suitable for large windowed folding carton. PET film can serve in sub-zero temperatures for frozen food application and high temperatures. PET is completely recyclable since it is a polymer similar to that used for the production of soft drink bottles.

Polypropylene

BOPP (Biaxially Oriented Polypropylene) film is one of the most versatile films in the plastic film market. BOPP films offer exceptional resistance to heat, moisture, oil/grease, acids and some solvents.

Due to its low cost and versatility, polypropylene film is the most commonly used for packaging with window in the food industry. Clarity, stiffness and resistance and reasonable price make it a very competitive film. But it is not suitable for large window patches, where structural strength is required.

Other types of films are available for packaging with window such as Polyethylene (used for tissue boxes), acrylic (excellent clarity and gloss characteristics) and PLA (biodegradable polyester derived from renewable resources, such as corn starch) for instance.

Film can also be coated for specific needs to add some additional features.

Packaging with window : what are the benefits?

Folding cartons can be windowed to enable the contents to be displayed, allowing the customer to have a direct eye contact with the product. With a windowed packaging, the consumer has an exact idea of shape, color and physical aspect of the product.

Folding cartons can be windowed to enable the contents to be displayed, allowing the customer to have a direct eye contact with the product. With a windowed packaging, the consumer has an exact idea of shape, color and physical aspect of the product.

A windowed packaging allows also manufacturers to showcase the primary packaging. This is particularly important in beauty and cosmetics, where manufacturers invest a lot on primary packaging (perfume bottles for instance).

Only perfectly manufactured packaging with window will have such a positive impact for the consumers. Make sure your windowed boxes are manufactured by a renowned professional. Do not hesitate to contact us(netpak@netpak.com) in order to discuss potential collaboration opportunities, and solutions that we can bring to you.